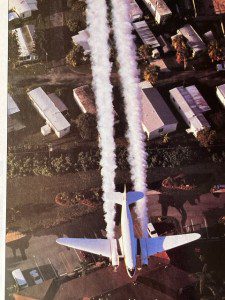

Pampering the ‘Dragon Lady’

Retired SMSgt TJ NIZNIK was a U-2 Crew Chief

Everything about the U-2 is unique. The U-2 was designed for a very specific mission, and the designer of the U-2, Kelly Johnson, once said, and I paraphrase, “If you want this aircraft to go high, I cannot design it to military specification”. The U-2 is known to save weight. For instance, there are very limited access panels. The requirement of having 2-3 threads of a screw protruding past the nut plate was reduced to being flush with the nut plate. Every pound of weight saved is a foot higher in altitude, and altitude is survivability. There are no self-sealing fuel cells on this jet. The U-2 is a wet wing, meaning the entire wing, from the wing tip to the fuselage, is all fuel. No single point refueling for this jet, nope it’s all over the wing refueling. There are 6-8 Crew Chiefs assigned to the aircraft, which is very unlike the rest of the Air Force, where 2-3 are typical.

The U-2 is a groundcrew nightmare. This is the only aircraft in my career where there is a file system of manufactured blueprints on hand because the tech data may only say remove and replace item X. Well, in any other military standard aircraft the tech data will be step-by-step how to remove and reinstall a part, with pictures and part numbers for consumable items. Not this jet.

The tech data will tell you what to do, but to find out the list of consumables, the ‘angle to the dangle’ of each fitting to be installed, etc, you will have to pull the blueprint and take all of the references from that. Now, I left the program in 2002, and they have been diligently working on changing the tech data to become more to standards. Another unique item is that this is the last taildragger in the inventory. With a bicycle landing gear and outboard wing pogo to prop up the wing during ground movement, this aircraft cannot turn on a dime.

It needs space, and some pilots misjudge their turn and get stuck on a taxiway, only to be rescued by a bunch of Crew Chiefs who will push back the jet and manually realign him. To fix a hydraulic leak in the engine bay, the jet has to be placed on a fuselage dolly, the tail section is removed, the engine is removed, and then one can tighten the fitting. Then it’s a 23-36 hour job to reinspect the entire inside and have Quality Assurance Inspections performed after you just inspected it before you can begin reinstalling everything. This is a time-consuming jet. However, every effort to eliminate this jet from the inventory has met in disaster because no other platform can do what this aircraft can.